Project drilling and insert heatet inserts

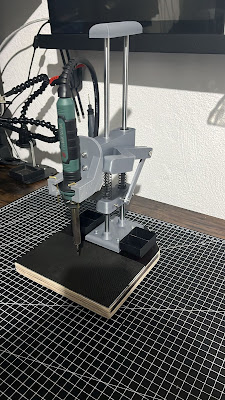

This time, my latest project is about finding a cost-effective solution for inserting heated inserts into 3D printed objects with precision, as freehanding often results in crooked threads. In addition, I wanted to be able to change the tool heads at the same time, so that, for example, my cordless Dremel can be used as a drill press.

I think I've really succeeded with this design. The print files also include a blank tool head so you can use your own tools.

The height is variably adjustable by means of two clamping screws on the lower part.

The stroke is variably adjustable from 60-180mm by using additional springs.

Here is an example of the precision, where the Dremel was equipped with a 3mm drill bit and was applied to the part 3 times.

This is an overview of the printed parts. The assembly is done using heated inserts and M3 screws at the following points, a BOM of the other required parts can be found below.

Non-printed parts (AliExpress links: cost about 10€)

2x 8mm stainless steel rod (length 350mm)

2x Spring 60*15mm (minimum)

3x LM8UU linear bearing (8mm inner diameter, 15mm outer diameter, 24mm length)

6x M3x4x4

M3 screws in various lengths

2x M3x14mm

1x M3x20mm + 3x M3 Mutter als Abstandhalter

1x M3x25mm

2xM3x12mm

Base plate (I used 18mm plywood)

The assembly can be seen in the pictures, but it is also self-explanatory.

You want to buy the Files?

Here`s your Link: Buy & Download

Wanna support me?

Comments

Post a Comment